ARE COLLABORATIVE ROBOTS THE NEW MUST-HAVES FOR METAL STAMPING AND PUNCHING?

In recent times, manufacturers around the world are showing an increasing interest in automating their production processes. They have good reasons to do so, as the use of collaborative robots can yield higher productivity, efficiency, lower costs in general.

Collaborative robots and their role in modern metal production

Even just about a decade ago, many manufacturers were reluctant to consider the use of robots in their production lines.

It was mostly due to high costs, and the programming expertise that was necessary for setting up and modifying the actions of the collaborative robots. It becomes increasingly important for manufacturers to understand that even though automation might have been expensive years ago, now is the time to reconsider it.

The high-level competition within robotics and automation has resulted in lower costs, and technological advancements have allowed companies to leverage these technologies and realize substantial benefits from them.

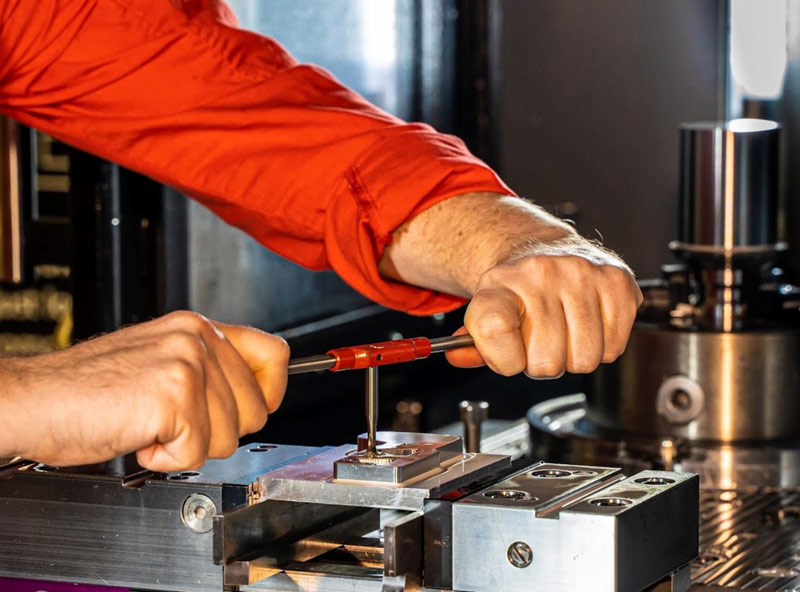

Manufacturers can use robotic solutions today to help their workforce with a host of tasks that are faster, safer, and cheaper this way. Metal punching and stamping are two examples of tasks, where robots can provide high efficiency and precision in the production process.

Stamping and Punching: What is the difference?

Talking about metal stamping means referring to the set of operations performed to obtain specific shapes on a workpiece. Basically, during the metal stamping process, an entire metal part with all the desired features worked into the end product can be achieved.

The cost of stamping is generally higher, and it is much better suited for mass production purposes when our goal is to produce entire metal parts.

Metal punching, on the other hand, is the process performed to achieve a specific shape, form on a metal part. Punching is better for the production of prototypes and small production quantities.

Robots can become invaluable additions to a manufacturer’s press line. But what exactly are these main benefits?

How can collaborative robots support stamping and punching processes?

- Short changeovers

Traditionally, long changeover times (i.e.: 1,5-2 hours) were considered the standard.

Imagine a massive metal part that has to be transferred to the next workstation manually. It not only demands a long time, but the task itself poses a considerable safety risk to workers too. With the support of automation, press lines can maintain flawless production as opposed to just idling, and waiting for the manual transfer to the next station.

The equation is simple: short changeovers, mean more changeovers per day, which results in higher output.

- More flexibility

The introduction of cobots in connection with cobot-cells has helped manufacturers to increase their flexibility in the production process. Traditional robots typically require a relatively large working space, they need to be programmed by an expert, their perimeter needs to be guarded, and they are not easy to move around.

Meanwhile, cobots can work alongside humans safely, be programmed without knowledge in programming, and can be moved easily around the production lines.

- High quality and data support

Advanced vision systems and high-resolution images allow collaborative robots to examine and evaluate the quality of work that was produced at the lines. This can provide fast, scalable, and precise feedback, which is essential to reduce the scrap produced and increase production quality.

Moreover, collaborative robots used in manufacturing are becoming smarter too. Through the use of AI applications in state-of-the-art robots, manufacturers can leverage the large amount of data collected during production and gain useful insights, helping them in optimizing the processes.

Manufacturers are still just exploring the vast opportunities robotic automation can provide them. Companies that follow these trends have a good chance of having an advantage over their competition in the long-run.